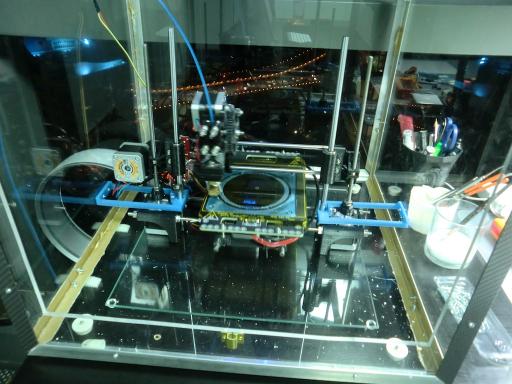

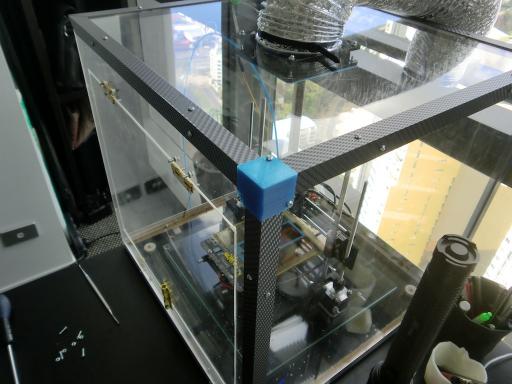

The picture below shows the brackets I've added to the box, these serve the purpose of keeping the printer in the centre. As the extruder pull the filament through, it tends to move the printer around, also the vibrations from printing were moving the printer inside the box, so I decided to add some brackets to hold the printer in the centre.

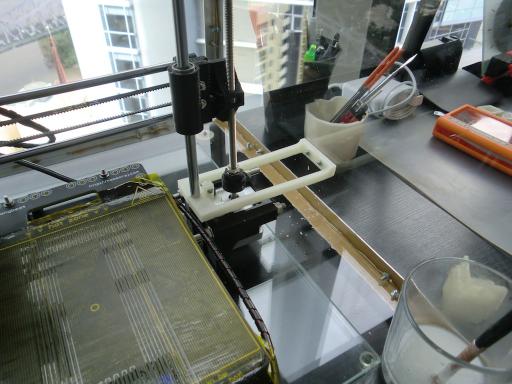

I went through a number of designs for the brackets...

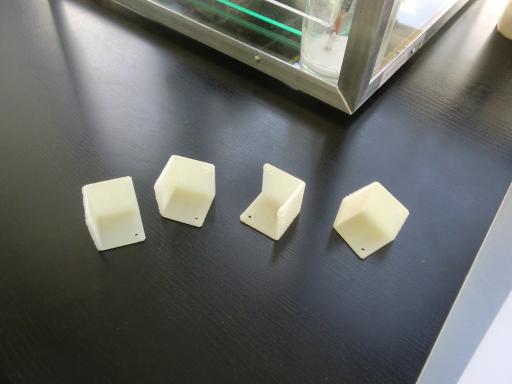

Eventually I settled on the following:

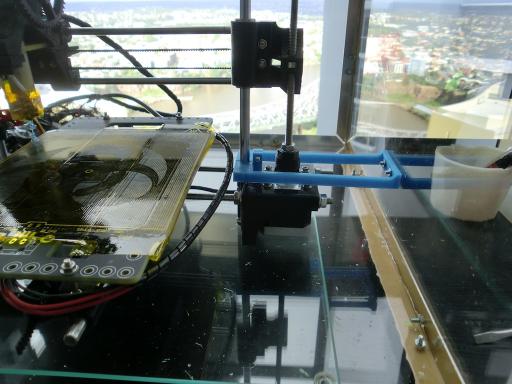

In addition to the brackets to hold the printer in place, I added some Z-axis stabilisers to the box. These are not as rigid as the bottom brackets to allow some movement, they also have a lot more surface area to help spread the vibrations.

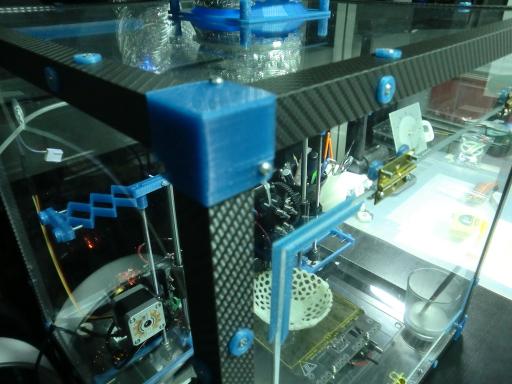

Now that the printer was secure inside the box, I wanted to cover up the corners of the box because they had some sharp edges. I designed a corner piece just for this. My original design was very simple.

In a later version of the corner piece I've added some extra bits on the inside to make take the width of the aluminium into account. This is what the final result was like:

The next entry will talk about making the box look nice by wrapping the aluminium corners into carbon fibre vinyl.

Part 4 is here.

-i